Page 1 of 2

Engine issue - assistance in Germany

Posted: Mon May 08, 2023 6:39 am

by Bela

I've been the owner since 2019 and we've had a lot of fun with our MM 1000. It just needed maintenance and a few minor touches.

Over the weekend there was an engine rattle and I suspect it is the crankshaft. We towed the car home. In the past I have not worried about serious engine failures because my plan was to purchase a Charles Ware remanufactured engine in such a case. But that source no longer exists.

I have had bad experiences with engine overhauls because such an order from a workshop regarding my XPAG (MG TD) failed. I'm still looking for a solution. The workshop was not specialized. I thought the XPAG was a simple machine and a good engine rebuilder could do the job. That was not a good idea.

Is there a source for an rebuild engine with a good reputation like Charles Ware?

Is there an MM specialist in Germany?.

Re: Engine issue - assistance in Germany

Posted: Mon May 08, 2023 7:48 am

by ManyMinors

Charles Ware did not recondition engines. They only bought them in and sold them on. You can still purchase one from ESM or other specialists.

A pity you had a bad experience before. Both engine are indeed simple units, as you know.

Re: Engine issue - assistance in Germany

Posted: Mon May 08, 2023 3:59 pm

by oliver90owner

Over the weekend there was an engine rattle and I suspect it is the crankshaft.

I would be making sure of the issue(s) before taking an unnecessary route for repair.

Some rattles can be quite ‘minor’ issues that are relatively easily/cheaply resolved.

Re: Engine issue - assistance in Germany

Posted: Mon May 08, 2023 6:11 pm

by Bela

ManyMinors wrote: ↑Mon May 08, 2023 7:48 am

.... You can still purchase one from ESM or other specialists....

I didn't see an engine or hull engine at ESM. Who are the specialists shipping to Germany?

oliver90owner wrote: ↑Mon May 08, 2023 3:59 pm

I would be making sure of the issue(s) before taking an unnecessary route for repair.

Some rattles can be quite ‘minor’ issues that are relatively easily/cheaply resolved.

Yes you are right. First you need a proper diagnosis.

Two master mechanics accompanied us and checked both with a wooden stick. They recommended driving no further and going to the shop to check the oil for abrasion and remove the oil pan. Both typed on a connecting rod bearing. I thought it might be loose clutch springs. I wear hearing aids though, so I can't be sure. That's why I take the first diagnosis seriously.

Re: Engine issue - assistance in Germany

Posted: Wed May 10, 2023 4:37 pm

by Bela

With a little help from my friend, the culprit seems to have been isolated. When cylinder 4 was unplugged, the rattle went away. I'm going to remove the sump to inspect it and take a look inside the bore with an endoscope.

Re: Engine issue - assistance in Germany

Posted: Wed May 10, 2023 5:06 pm

by philthehill

Remove No: 4 crankshaft bearing cap and see what you find.

Any copper showing through the white metal will indicate a bearing failure. Measure and examine the crankshaft journal for wear, ovality and scoring.

Re: Engine issue - assistance in Germany

Posted: Wed May 10, 2023 8:07 pm

by mowogg

This might seem an odd suggestion but are you sure it's not a head gasket fail between 3 and 4.

Running an engine with thr head gasket gone can sound very odd, and could fit your descriotiin

Are you able to do a compression test?

Re: Engine issue - assistance in Germany

Posted: Wed May 10, 2023 8:20 pm

by Bela

Thanks for that hint. It goes like the hint from philthehill on the to do list. In addition a pressure drop measurement will show more.

Re: Engine issue - assistance in Germany

Posted: Mon May 22, 2023 1:25 pm

by Bela

Bela wrote: ↑Wed May 10, 2023 4:37 pm

With a little help from my friend, the culprit seems to have been isolated. When cylinder 4 was unplugged, the rattle went away. I'm going to remove the sump to inspect it and take a look inside the bore with an endoscope.

I have done and find worn connecting rod bearings. I guess the crank itself could be polished. The seize is standard with 41,28 mm. I'll append pics later.

Is it possible to remove half the main beaing in the same manner to see what's up?

Re: Engine issue - assistance in Germany

Posted: Mon May 22, 2023 1:31 pm

by Monty-4

All the conrod big-end bearings can be checked by just removing the sump, the centre main can be checked like this too but the front and rear main bearings require further engine dissassembly.

Watch out for thrust washers falling on your head, don't ask me how I know!

Re: Engine issue - assistance in Germany

Posted: Mon May 22, 2023 10:41 pm

by Bela

Now the pics of the crank after polish

Re: Engine issue - assistance in Germany

Posted: Mon May 22, 2023 10:44 pm

by Bela

Pics of the bearings

Re: Engine issue - assistance in Germany

Posted: Tue May 23, 2023 6:07 am

by Bela

If I'm going to fit new bearings in place of worn parts - what is important regarding lubrication and starting engine first time?

Re: Engine issue - assistance in Germany

Posted: Tue May 23, 2023 8:37 am

by philthehill

I assume that you have measured the crank journals and they are serviceable and within the wear limit?

When fitting the bearings coat the bearing rubbing faces in engine assembly fluid.

https://www.ebay.co.uk/itm/403648810791 ... R86i8_iIYg

If you have a oil pump priming plug (located at the N/S/R of the block) remove the plug and prime the oil pump.

If you do not have a priming plug you can remove the block to oil filter pipe banjo bolt (located at the O/S/R of the block) and inject engine oil down the oil gallery to the oil pump. When the oil pump is full of oil refit the banjo bolt not forgetting the two copper washers.

Remove the plugs.

Turn the engine over on the starter motor until the oil pressure light goes out. Turn the engine for at least another 30 seconds on the starter to get the oil around the engine.

Refit the plugs and start the engine. Do not rev the engine until you are sure that oil is getting around the engine.

Remove rocker cover and check that oil is getting to the top of the engine.

At the first opportunity change the engine oil and filter as bearing crud could have been trapped in a oil gallery and is now circulating around the engine.

No doubt you will be replacing the oil filter element.

If you have a canister type filter fill the oil filter with oil before screwing to the filter head.

You can prime the element type oil filter by injecting oil down the block to oil filter head pipe.

Priming the oil filters removes any chance of the oil pressure not coming up fast enough leading to scuffing of the white metal bearings.

Re: Engine issue - assistance in Germany

Posted: Tue May 23, 2023 3:19 pm

by Bela

philthehill wrote: ↑Tue May 23, 2023 8:37 am

I assume that you have measured the crank journals and they are serviceable and within the wear limit?

Yes - the crank has never been ground! I measured 41.28 mm with vernier calipers. To be on the safe side, I ordered a micrometer.

Thank you for the advice !

Re: Engine issue - assistance in Germany

Posted: Tue May 23, 2023 5:30 pm

by oliver90owner

Do check for ovality. One single measurement on each journal may be deceptive.

Re: Engine issue - assistance in Germany

Posted: Sun May 28, 2023 9:51 am

by Bela

Part will arrive on Tuesday.

In the meantime I had a look at the WSM.

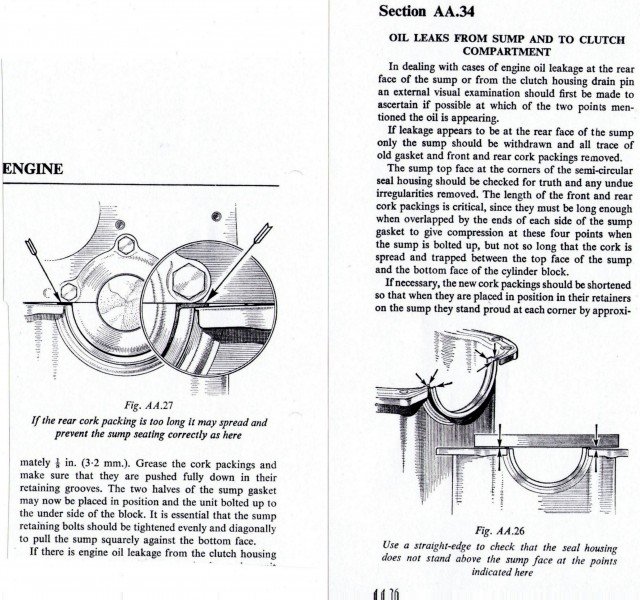

Because I'm not a native speaker and I'm doing the work for the first time, I have a problem of understanding. It's about sealing the oil pan to the crankshaft. Chapter AA. 2 of the WSM, it is required that these strips protrude by 3/32" when inserting the seal. Chapter A.2 contains Figures A.2 and A.3. Chapter AA.34 also includes a warning in Figure AA.27 that folding the seal can cause a leak. What exactly happens at this point? The photo of the removed oil pan shows the mating connection to the other seal. What happens to the seal that protruded before installation? I think it is compressed and not just into the seat inserted but firmly pressed in? In Chapter AA.34, the overhang is no longer specified as 3/32" but as 1/8". What is correct? Does the overhang with the stated dimensions have to continue after the seal has been pressed in?

Re: Engine issue - assistance in Germany

Posted: Sun May 28, 2023 10:09 am

by philthehill

The correct height for the sump cork packing above the sump flange is 1/8". If required trim the cork to suit.

The cork packing must be well greased before fitting. When the sump is pulled to the block the cork packing is compressed back into the sump cork packing retaining channel. The grease aids the sliding/compression of the cork packing.

The cork packing when pressed into the retaining channel should still protrude 1/8" above the sump flange at either end.

- Sump gasket 1.jpg (106.54 KiB) Viewed 1006 times

Grease the sump side gaskets and fit those first. The cork packing presses against the underside of the side gasket to complete the seal.

There is no need for any mastic or other type of sealant.

Re: Engine issue - assistance in Germany

Posted: Sun May 28, 2023 10:31 am

by Bela

Thank you Philthehill for you ongoing advice

Re: Engine issue - assistance in Germany - threads of oil pan bolts

Posted: Mon May 29, 2023 8:00 pm

by Bela

I focused on the bearing shells. When cleaning the bolts for the oil pan, I saw that 3 threads were worn out. I've had success twice trying to fix the thread of the hole. So it seems I need thread cutters. But which thread is it? Living in Germany, I don't own many non-metric nuts and bolts. I tried 1/4 BSF but turning the screw stops at about 1/4 inch..